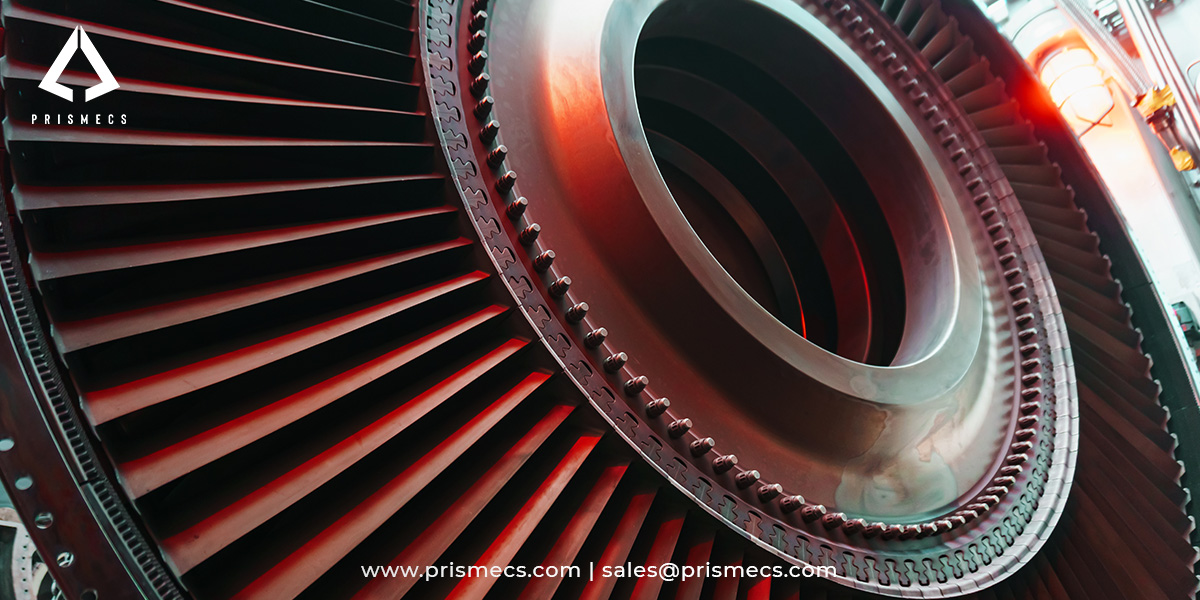

Industrial gas turbines are the backbone of critical power infrastructure in oil & gas, petrochemical plants, and large-scale energy projects. The lubrication system plays a central role in maintaining operational efficiency, reducing wear on high-speed bearings, and preventing downtime in mission-critical environments.

By precisely managing oil flow, pressure, and temperature, these systems ensure turbines operate at peak efficiency across all load conditions. Understanding lubrication components and their function is essential for EPC Services teams, asset owners, and operators seeking to maximize uptime, extend equipment life, and reduce lifecycle costs.

Types of Lubrication Systems in Industrial Gas Turbines

Industrial gas turbines rely on two main lubrication designs optimized for high-performance energy applications:

Wet-Sump System

This system stores oil within the turbine assembly, enabling rapid circulation to bearings and critical moving components. Wet-sump designs are often used in smaller industrial turbines and fast-start backup power units, ensuring reliable lubrication during continuous operation with simplified maintenance workflows.

Dry-Sump System

In large-scale industrial and utility turbines, oil is stored in an external reservoir, allowing precise thermal control and superior oil management. Advanced scavenge and pressurization pumps circulate oil efficiently even under high-load or extreme environmental conditions. Dry-sump systems enhance component longevity, operational reliability, and turbine availability, critical for industrial plants, IPPs, and utility operators.

Components of a Gas Turbine Engine

Many components are part of a gas turbine engine, such as bearings: a lubricant supply system specifically lubricates a gas turbine engine. It includes a significant lubricant moving circuit and an auxiliary lubricant rotating circuit.

It ensures a sufficient lubricant supply to the lubricating chamber and chambers beneath all operating situations. The circulatory circuit is known as the engine start-up & for replenishing lubricant into the primary circuit during normal flight conditions.

Role of Lubricating Oil in Industrial Turbine Performance

Lubricating oil is the lifeblood of industrial gas turbines. In large-scale energy assets, it performs multiple strategic functions:

- Thermal Management: Circulates around high-speed bearings to dissipate heat, preventing overheating and maintaining optimal efficiency.

- Friction Reduction: Ensures smooth rotation of components, reducing wear and extending turbine lifecycle.

- Pressure Stabilization: Maintains consistent oil pressure under variable load conditions, critical for continuous operation.

- Operational Resilience: High-quality turbine oil supports industrial and utility-scale turbines, minimizing the risk of forced outages in oil & gas, petrochemical, and power generation facilities.

Effective lubrication directly impacts CAPEX and OPEX, influencing maintenance schedules, downtime risk, and overall energy output. Prismecs’s expertise in turbine lubrication, spare parts management, and O&M ensures industrial operators can maximize uptime and long-term asset value.

Read More: How Gas Turbines Are Transforming the Future of Energy Production

Key Components of a Gas Turbine Engine’s Lubrication System

A turbine system relies on various components to ensure proper lubrication and optimized performance. Below are the critical parts of the lubrication system.

Oil Tank

Usually, it has an oil pump, scavenge & pressure inlet strainers, pressure outlet ports, and an oil filter. It also has mounting bosses for the oil pressure control and temperature bulb linkages.

A typical oil tank is developed to provide the turbine engine with plentiful oil during any operation. In a gas turbine engine, this process is completed by a swivel outlet assembly mounted on the inner side of the oil tank, a horizontal baffle mounted in the middle of the tank, and two flapper check valves fixed on the baffle.

All oil tanks have expansion space, which permits the oil to expand after the bearings and gears absorb the temperature. A few oil tanks also have a deaerator tray, which separates air from the petroleum returned to the upper side of the tank by the scavenger system.

Oil Pump

The oil pump is crucial for supplying oil under pressure to different turbine engine components. It also facilitates oil circulation through coolers before returning it to the oil tank.

Oil pumps may include pressure supply elements and scavenge components, especially in dry-sump systems. Some oil pumps have separate pumping components controlled by multiple shafts, ensuring efficient lubrication. The gear-type oil pump consists of a pressure oil section and a scavenging section to regulate oil distribution efficiently.

Turbine Oil Filters

Turbine oil filters are essential for removing contaminants from lubricating oil. They also prevent the wear of antifriction balls and roller bearings, ensuring the engine's high-performance operation.

Oil flows through the filter from the outer casing into the filter body. Filters trap impurities and are made of paper or stainless steel mesh. Laminated paper filters are replaceable, while metal mesh filters ensure durability.

Oil Pressure Relief Valve

The oil pressure relief valve prevents excessive pressure buildup within the turbine system. When pressure exceeds preset limits, it returns excess oil to the oil pump's inlet side.

This component is critical in turbines with integrated oil coolers, preventing damage to the cooler’s thin-walled construction. The relief valve helps maintain optimal oil pressure for optimized performance.

Conclusive Remarks

Here, we have discussed the major components of the lubrication system of gas turbine engines and provided all the essential information about the process. Prismecs is a platform that can deliver all kinds of oilfield and gas-related services.

We provide strategic global markets for operations with essential maintenance requirements. Our strong supply chain is responsive to the gas turbine engine parts, repair, and manufacturing, reducing downtime in E&P environments. You can contact us for any turbine engine-related services. To avail of our services, call us at +1 (888) 774-7632 or email us at sales@prismecs.com.

Tags: gas turbine lubrication industrial turbine maintenance turbine bearings and pumps turbine oil system power generation equipment

recent posts

Power Generation

10 minutes read

How to Maximize Uptime in Power Generation Plants

Discover how Prismecs power plant maintenance helps operators prevent outages, protect revenue, and keep turbines running at peak performance. Learn h...

Renewables

8 minutes read

Opportunities in Renewable Energy Development

Explore Renewable Energy Development strategies focused on grid stability, faster deployment, and resilient power systems with Prismecs. Plan your nex...

Press Release

2 minutes read

Altaaqa Global & Prismecs Form Strategic Cooperation to Accelerate Modular Power Deployment Across USA

Prismecs and Altaaqa Global Announce Strategic Cooperation to Accelerate Modular Power Deployment in the United States Houston, TX & Dubai, UAE – Febr...

Procurement

9 minutes read

Complete Guide to Industrial Procurement Services

Explore Industrial Procurement Services for power and oil & gas projects. Cut delays, secure critical equipment, and build resilient supply chains wit...