Turbine engines are high-performance mechanical devices that generate energy by compressing air and burning fuel. A critical component in this energy conversion process is the compressor. Whether in jet propulsion or industrial air conditioning systems, the compressor reduces air volume. It increases pressure and supports combustion and airflow across the engine. In this article, we take an in-depth look at how compressor parts operate in turbine engines. We explain how these parts relate to pneumatic tools. We show why keeping these components functioning properly is essential for overall engine performance.

Understanding the Compressor’s Role in Turbine Engines

In a typical gas turbine engine, the compressor increases the pressure of the air before it enters the combustor. They mix the pressurized air with fuel and ignite it to drive the turbine, generating mechanical energy. Compressor pumps in AC units and condenser coils in HVAC systems follow a similar process. This process depends on highly efficient air compression to achieve the desired energy output.

A compressor is more than just a moving part; it supports a turbine’s overall performance. It directly impacts efficiency, fuel consumption, and the turbine’s power output during operation. The compressor and turbine are primarily on the same shaft. The compressor drives and compresses the air. Then the fuel mixes and passes through the gas turbine at high pressure. After all processes, it generates energy. The engine compressor section must provide a sufficient amount of compressed air to satisfy combustion requirements. Its other purpose is to provide bleed air for many systems.

Compressor Performance at High Altitude

In large-scale industrial turbines, efficient air compression is essential to maintain optimal power generation, especially in Renewable Energy projects and IPP facilities. Leveraging Technology and Consulting ensures turbines operate at peak efficiency under variable loads.. The compressor ensures consistent airflow and pressure for combustion, enabling reliable energy output and reducing fuel consumption across power plants and industrial facilities.

Compressor Function in Turboshaft Engines

In industrial gas turbines, the compressor section delivers high-pressure air to the combustor, ensuring stable mechanical energy transfer to the turbine shaft. Efficient compressor operation directly impacts fuel efficiency, system reliability, and uninterrupted power generation in factories, pipelines, and energy-intensive plants.

How Compressors Operate in Turboprop Engines

In industrial turbines, the compressor supplies high-pressure air for combustion, driving the turbine shaft to generate consistent mechanical energy. Precise control of airflow ensures optimal energy efficiency and sustained power output for continuous industrial operations, from manufacturing plants to power generation facilities

Compressor Similarities with Internal Combustion Engines

Like an internal combustion engine, a gas turbine relies on the careful mixing and compression of air and fuel. The compressor compresses air at the front of the engine, making it suitable for ignition. This similarity extends to other systems like AC systems, where air conditioning compressors handle air compression to support cooling. Both systems benefit from well-regulated airflow and pressure control.

Role of Compressors in Industrial Gas Turbines

An industrial gas turbine needs a robust compressor section for efficient, large-scale power generation. The compressor section supplies high-pressure air essential for the turbine’s power generation process. The compressor compresses vast amounts of air, ensuring consistent combustion and rotation of the power turbine. Whether in factories, pipelines, or electrical grids, these systems demand high fuel efficiency and energy efficiency under constant load.

Compressor’s Location and Role at the Front of the Engine

Located at the front of the engine, the compressor serves as the first step in the turbine’s energy production cycle. Similar to air conditioning compressors, it conditions the air before it enters high-pressure combustion. Whether in a turbofan engine, turbojet engine, or turboshaft engine, it compresses air efficiently. It delivers air effectively to ensure smooth transitions through the combustion and turbine stages.

The Function of a Compressor in a Turbine Engine

The engine's compressor has the essential task of providing adequate pressurized gas to meet combustion requirements.

Role of Pressurized Gas in Internal Combustion

It increases the air pressure received at the inlet for improved combustion efficiency. Then, it provides the pressurized air to the combustion section at the higher pressure needed for efficient burning. This process plays a critical role in kinetic energy conversion within the turbine system.

Cooled Air and Electric Generation Process

The shaft turns the blades in the compressor into the turbine. It rotates the intake fan at the front, allowing cooled air to flow through different stages. This rotation takes energy from the high-energy flow that drives the fan and the compressor. The gases generated in the combustion chamber move through the turbine and spin its blades. These spinning blades eventually help generate electricity through an electric generator.

How the Compressor Connects to the Turbine

Both the compressor and turbine sit on a common shaft, forming a direct mechanical link. This setup creates a strong connection between the two components for efficient operation.

Transfer of Kinetic Energy Through Rotational Motion

As hot combustion gases expand through the turbine, they spin its blades, which in turn drive the compressor blades at variable speeds. This motion compresses the incoming air, reducing its volume and increasing its pressure.

How Air Passes and Powers Long-Term Engine Operation

As air passes through the compressor, it gains kinetic energy and becomes pressurized gas. This pressurized gas mixes with fuel in the combustion chamber. The ignition of this mixture releases intense heat and pressure. This release continues the rotation that powers both the compressor and turbine. The seamless energy flow keeps the engine working properly under varying operating conditions. It offers improved long-term performance and reliability in power applications.

Key Components of Turbine Engine Compressors

A turbine engine compressor typically includes three essential components: the impeller (rotor), the diffuser (stator), and the compressor manifold.

Impeller and Diffuser's Role in Kinetic Conversion

The impeller gathers incoming air and accelerates it outward through centrifugal force, converting it into kinetic energy. This high-speed airflow enters the diffuser, which slows it down for better combustion. The diffuser converts the slowed airflow into higher pressure to support efficient combustion.

Compressor Manifold and Heat Transfer Efficiency

The compressor manifold finally distributes the pressurized gas evenly to the combustor. These components function like refrigerant gas cycles in air conditioning systems. In both systems, heat transfer, cooled air, and pressure regulation remain critical. Steam turbine systems also show this similarity through their use of fluid dynamics. Fluid dynamics play a central role in maintaining performance in steam turbine systems.

Role of Compressor in Gas Turbine

Demand for gas power plants is increasing daily because of various benefits. Natural gas use is rising as a fuel since other fuels may include synthetic gas or alternatives. In a gas turbine, hot combustion gas circulates through the turbine, spinning its rotating blades. These blades drive the compressor, enabling a steady supply of compressed air.

Steam Turbine vs. Gas Turbine Energy Flow

In steam turbine power plants, the working fluid is water and steam. Gas turbine power plants use a mixture of air and fuel as the operating fluid. This fluid interacts with the turbine on one side and the compressor on the other, similar to the setup in a jet engine.

General Electric Systems and Electricity Generation

As air passes through the compressor, it is compressed, mixed with fuel, burned, and expelled through the turbine. Companies like General Electric manufacture systems that follow this principle to maximize heat transfer efficiency. These systems generate electricity for industrial applications and support power needs in commercial operations.

Types of Compressors in Turbine Engines

Turbine engine compressors come in two primary types:

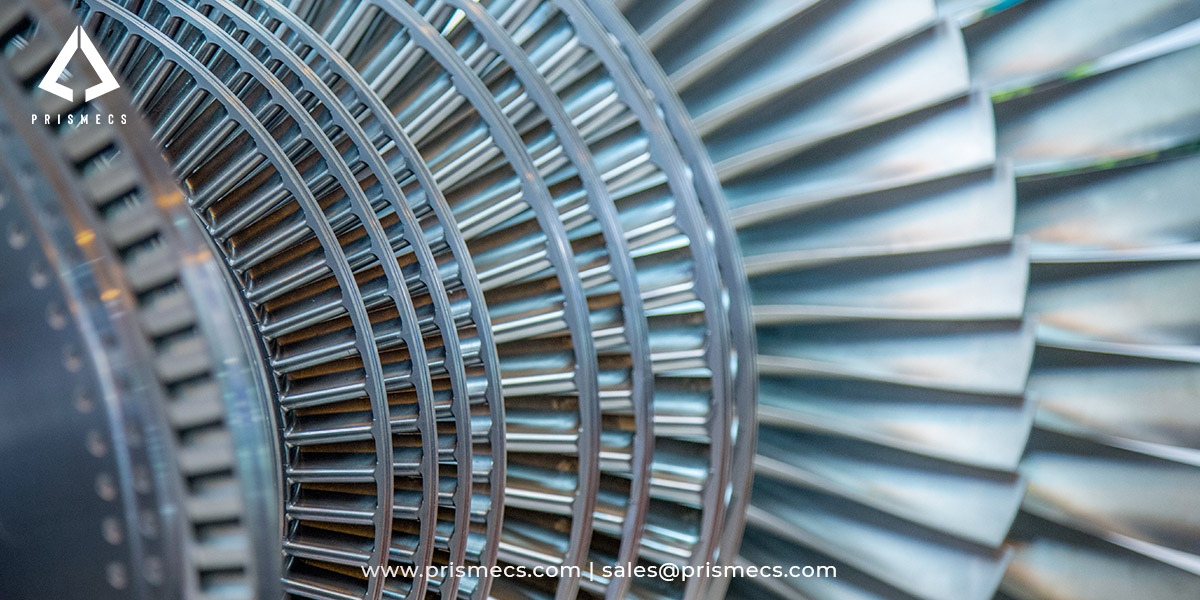

Axial-Flow Compressors

In axial flow compressors, air moves along a straight path parallel to the shaft. This type is common in jet engines and large industrial turbines.

Key features

- High efficiency at a smaller volume

- Multiple rotor and stator blade stages

- Compression ratio is typically around 1.25:1 per stage

- Suitable for engines requiring variable speeds

How it works

- Rotor blades spin and push air backward

- Stator blades slow down and increase air pressure

- Each stage further compresses the air

This design ensures a continuous and smooth flow of air for proper turbine function. It allows the turbine to operate much like pneumatic tools that rely on consistent air pressure. Pneumatic tools perform efficiently when they receive steady and uninterrupted airflow during operation.

Centrifugal-Flow Compressors

Centrifugal compressors use centrifugal force to accelerate air outward from the center of rotation.

Key components

- Single or double-entry impellers

- Diffuser

- Plenum chamber (used in double-entry designs)

Single-entry impellers allow simpler air ducting in engine designs. Double-entry impellers serve engines needing higher airflow. These require more complex ducting because of their increased performance demands. These configurations help manage air intake effectively. They work like an efficient AC unit, managing pressure and temperature. The compressor and condenser coil in an AC unit handle these tasks smoothly. Auxiliary air intake doors in centrifugal compressors function similarly to compressor pumps in HVAC systems, ensuring sufficient airflow during startup or ground operation.

Get Expert Help for Turbine Compressor Issues

Prismecs has excellent expertise in replacing compressor parts. If you're noticing issues with your turbine engine compressor parts, consider a detailed inspection. Reduced output or inefficient airflow often signals the need for a thorough performance check. Call our experienced team today at +1(888) 774-7632 or email us at sales@prismecs.com to schedule a consultation.

Our technicians understand how a well-maintained mechanical device should function in all situations. They stay ready to ensure your compressor works properly under every operating condition. Your compressor performs like a finely tuned air conditioning system or high-performance AC unit.

Tags: Turbine Engine Compressor Boiler Gas Turbine Compressor Gas Turbine Engine Compressor Turbine Engine Parts Turbine Compressor Compressor Turbine Compressor Components Compressor In Jet Engine Jet Engine Compressor Function of The Compressor Turbine Engine Components Parts of a Turbine What Is The Function of The Compressor Difference Between Turbine And Impeller Turbine And Compressor Role of Compressor Parts of The Compressor

recent posts

Power Generation

10 minutes read

How to Maximize Uptime in Power Generation Plants

Discover how Prismecs power plant maintenance helps operators prevent outages, protect revenue, and keep turbines running at peak performance. Learn h...

Renewables

8 minutes read

Opportunities in Renewable Energy Development

Explore Renewable Energy Development strategies focused on grid stability, faster deployment, and resilient power systems with Prismecs. Plan your nex...

Press Release

2 minutes read

Altaaqa Global & Prismecs Form Strategic Cooperation to Accelerate Modular Power Deployment Across USA

Prismecs and Altaaqa Global Announce Strategic Cooperation to Accelerate Modular Power Deployment in the United States Houston, TX & Dubai, UAE – Febr...

Procurement

9 minutes read

Complete Guide to Industrial Procurement Services

Explore Industrial Procurement Services for power and oil & gas projects. Cut delays, secure critical equipment, and build resilient supply chains wit...