In the ever-evolving industrial landscape, the demand for reliable, efficient, and scalable power generation solutions is continually growing. Whether you operate in the oil, gas, petrochemical, or manufacturing industries, the energy supply remains critical. Gas Turbine Power Stations stand out in industrial energy generation. They help deliver energy efficiently to various sectors through reliable technology.

Gas turbines support both mobile plants and large systems with power, precision, and performance. Engineers managing electrical systems or plant operators can gain from understanding this essential technology. This guide explains what gas turbine power stations are, how they operate, and why industries choose them.

What Is a Gas Turbine Power Station?

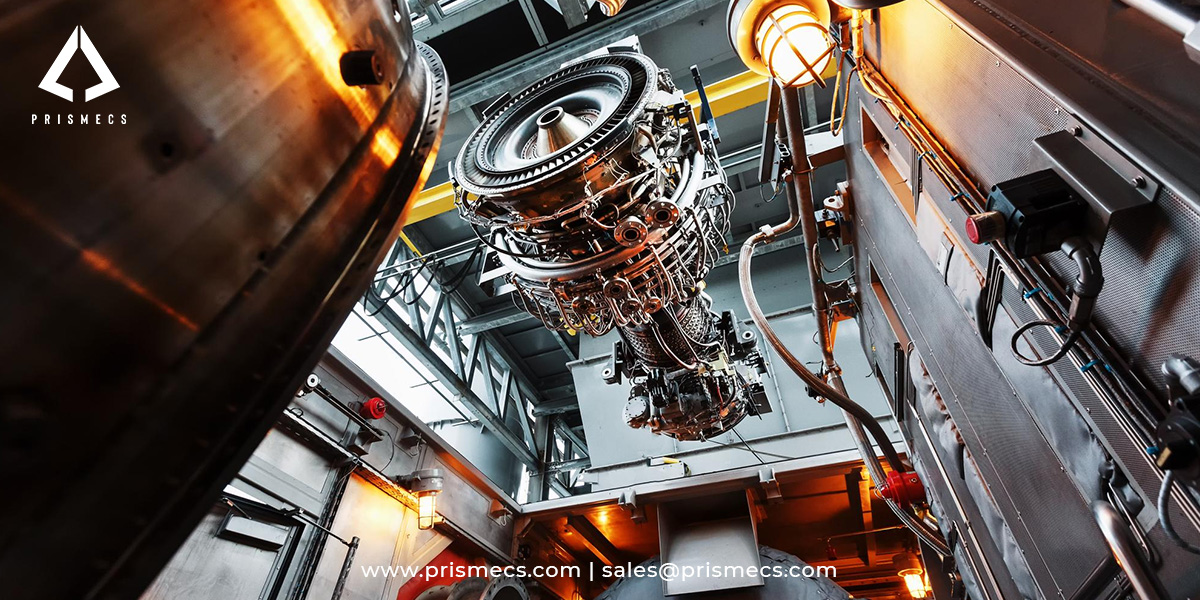

A Gas Turbine Power Station generates electricity using a gas turbine engine. This engine technology originated from jet engines. It converts chemical energy into electricity through a defined process. The process includes compressing air, burning fuel, and rotating a turbine.

Gas turbines run at high speeds under intense heat conditions. These qualities make them suitable for large-scale power generation. The systems are compact, responsive, and deliver high power quickly. Industries use them for steady operations and emergency power supply.

Combined heat and power (CHP) systems can improve turbine efficiency. These systems recover exhaust gas to generate more energy using a heat exchanger.

How Gas Turbine Power Stations Generate Electricity

Gas turbine power stations convert natural gas energy into electricity. The working principle of a gas turbine power station involves three main components. These components include the compressor, the combustion chamber, and the turbine.

Air Compression

The turbine pulls in ambient air and compresses it to high-pressure ratios using axial or centrifugal compressors. This step is essential for enhancing combustion and achieving higher efficiency.

Combustion

Compressed air mixes with natural gas inside the combustion chamber. Ignition rapidly raises the temperature. This process releases chemical energy.

Turbine Rotation

The high-energy exhaust gas expands through the turbine blades, causing the shaft to spin and generating mechanical energy. That mechanical energy drives a generator, producing electricity. This process is efficient, fast, and scalable. It’s the same fundamental principle that powers modern jet engines, only adapted for electricity generation in industrial environments.

Gas turbine stations sometimes work with nuclear power plants to boost energy efficiency. They also integrate combined heat and power systems to enhance overall energy efficiency.

Combined Cycle: Turning Waste into Power

Traditional gas turbine systems emit waste heat, which, if unused, represents a lost opportunity. Combined Cycle Power Plants (CCPP) solve this issue by pairing gas turbines with steam turbines. Here's how it works:

- Hot exhaust gases from the gas turbine pass through a Heat Recovery Steam Generator (HRSG).

- The HRSG uses this waste heat to produce steam.

- That steam drives a steam turbine, creating additional electricity.

This configuration drastically improves thermal efficiency, often reaching 60% or higher. The integration of a Recovery Steam Generator HRSG not only boosts output but also lowers fuel costs and emissions.

Global Gas Turbine Services Market: Growth and Prismecs Advantage

The gas turbine services market is rapidly expanding, projected to grow from $32.09 billion in 2025 to $47.06 billion by 2029 at a CAGR of 9.7%. This surge is driven by aging turbine fleets, rising industrial energy demand, and the push for operational efficiency across sectors like oil & gas, petrochemicals, metals, and manufacturing.

Prismecs empowers industrial operators to capitalize on this growth with end-to-end gas turbine solutions. From engineering, procurement, and commissioning to advanced O&M services and technology-led performance optimization, we ensure that facilities maximize turbine efficiency, reduce downtime, and meet stringent environmental standards. By integrating combined cycle technology and smart energy solutions, Prismecs helps industries achieve scalable, reliable, and sustainable power generation turning market trends into measurable operational advantages.

Why Industries Choose Gas Turbine Power Plant Stations

Industrial environments prioritize power solutions that combine performance, flexibility, and efficiency. Gas Turbine Power Plant stations deliver on all these fronts.

High Speed and Rapid Start-up

Gas turbines offer high speed and quick start-up times. These features are crucial for facilities that require emergency power or backup systems. Unlike other forms of power generation, these stations can ramp up within minutes, avoiding costly downtime.

The LMS100 aeroderivative gas turbine ranks among the most efficient simple-cycle turbines in the world. Its advanced inter-cooled system delivers fast, reliable performance. It reaches full load in just 8 minutes. It offers emergency ramp speeds up to 500 MW per minute.

Scalable Power Outputs

Gas turbines power remote operations with compact mobile units. They support industrial zones with large-scale systems. Gas turbines deliver scalable power outputs tailored to diverse demands.

The 115 MW SC output of LMS100 shows this flexibility. It offers high-efficiency performance for mid-to-large industrial applications. These include mining sites, petrochemical facilities, and grid support.

You can utilize fast-deploying modular solutions to meet urgent power needs. Gas turbines also provide robust base-load generation when needed. They scale seamlessly to match your operational needs.

Fuel Flexibility and Clean Energy

Gas turbines primarily run on natural gas, a cleaner alternative to coal or oil. They produce lower emissions and help companies meet environmental standards. Some models can also handle synthetic fuels and hydrogen blends, allowing futureproofing as energy markets evolve.

A modern combined cycle gas turbine can cut emissions by 60% or more. It offers a cleaner option compared to a similarly sized coal-fired power plant. This makes gas turbines valuable as customers shift from coal to gas or other technologies.

Compact Design

Microturbines, some as small as a household refrigerator, deliver power outputs ranging from 25 to 500 kW. They are ideal for environments with limited space—their compact footprint and low emissions support on-site power generation in urban buildings and remote sites.

These turbines also work well in commercial facilities and hybrid renewable systems. They run on various fuels, adding flexibility. As the demand for distributed energy and decentralized power solutions grows, microturbines offer a reliable, efficient, and cleaner alternative to traditional diesel generators.

Read More: How Gas Turbines Are Transforming the Future of Energy Production

How Gas Turbines Outperform Internal Combustion Engines

Smaller-scale applications commonly use internal combustion engines. However, gas turbines deliver greater efficiency and speed in larger industrial settings. Gas turbines provide higher pressure ratios and more stable performance under continuous operation.

Gas turbines, especially aero-derivative models, achieve higher pressure ratios, ranging from 10:1 to 58:1. In contrast, traditional internal combustion engines typically operate at pressure ratios between 6:1 and 23:1.

Internal combustion engines focus on the compression and expansion of a gas within a cylinder. Gas turbines rely on continuous combustion and advanced compression stages. This allows for superior pressure ratios and efficiency.

Integration with Renewable and Smart Grids

Gas turbines also play a crucial role in modern power generation. Their ability to quickly respond to demand makes them ideal for renewable energy sources. They complement intermittent sources, such as solar and wind.

When integrated into smart grids, gas turbines provide fast and flexible power generation. This helps stabilize the grid, especially with variable renewable energy sources.

Unlike renewables, which depend on weather conditions, gas turbines can quickly ramp up or down in response to changes in demand. They fill power gaps and ensure a stable electricity supply. This fast response time is crucial for industrial processes that require a steady voltage and frequency.

The Future of Industrial Energy Lies with Gas Turbine Power Stations

In an era where reliability, efficiency, and environmental responsibility are more important than ever, a gas turbine power station provides an optimal solution for industries. Gas turbines set the standard in industrial power generation.

They power both compact mobile plants and large systems. Combined cycle technology enhances its efficiency in extensive systems. They deliver unmatched thermal efficiency, rapid scalability, and a cleaner path forward for energy-intensive sectors. Innovations in Heat Recovery Steam Generators enhance gas turbines.

Advanced materials improve high-temperature endurance. Integration with innovative technologies strengthens their performance. The gas turbine is not just a legacy solution. It is a cornerstone of the industrial future.

How Prismecs Can Support Your Industrial Gas Turbine Power Station Needs

Prismecs provides full-service power solutions. It offers end-to-end support for industries. These industries adopt or upgrade Gas Turbine Power Stations. From engineering and procurement to commissioning, we manage everything, from compact mobile plants to large complex systems.

Our team integrates turbines seamlessly. We also include components like combustion chambers and Heat Recovery Steam Generators. These are for combined cycle applications. We also provide comprehensive lifecycle services, including operations, maintenance, performance optimization, and overhauls, to maximize thermal efficiency and minimize downtime.

Bottom Line

Prismecs isn’t just a vendor; we’re your strategic energy partner. We bring technical depth, field experience, and agility to deploy cutting-edge gas turbine power plants.

Whether you’re building a new facility or modernizing an existing one, we power your industrial success. To take advantage of our gas turbine services, please get in touch with us at +1 (888) 774-7632 or email us at sales@prismecs.com.

Tags: Gas Turbine Power Station Steam Turbines Gas Turbine Power Plants Natural Gas Combined Cycle Power Plants Internal Combustion Engines Electricity Generation Thermal Efficiency Mechanical Energy Power Generation

recent posts

Power Generation

10 minutes read

How to Maximize Uptime in Power Generation Plants

Discover how Prismecs power plant maintenance helps operators prevent outages, protect revenue, and keep turbines running at peak performance. Learn h...

Renewables

8 minutes read

Opportunities in Renewable Energy Development

Explore Renewable Energy Development strategies focused on grid stability, faster deployment, and resilient power systems with Prismecs. Plan your nex...

Press Release

2 minutes read

Altaaqa Global & Prismecs Form Strategic Cooperation to Accelerate Modular Power Deployment Across USA

Prismecs and Altaaqa Global Announce Strategic Cooperation to Accelerate Modular Power Deployment in the United States Houston, TX & Dubai, UAE – Febr...

Procurement

9 minutes read

Complete Guide to Industrial Procurement Services

Explore Industrial Procurement Services for power and oil & gas projects. Cut delays, secure critical equipment, and build resilient supply chains wit...